Achieving the Perfect Fit: A B2B Guide to Sourcing Full Cup Bras?

Struggling to source full cup bras that balance comfort, support, and aesthetics? The answer lies in fabric choice, sizing precision, and vendor collaboration.

Full cup bras require breathable, supportive fabrics (like modal or power mesh), meticulous sizing grades for DD+ cups, and suppliers with BSCI/ISO certifications to ensure compliance and fit consistency.

Sourcing full cup bras isn’t just about ticking boxes—it’s about crafting a product that empowers wearers. Let’s break down the five pillars of successful B2B sourcing.

Premium Fabrics First: Selecting Materials That Support and Breathe?

Why do full cup bras fail? Often, it’s cheap fabrics that sag or irritate. The right materials make all the difference.

Prioritize fabrics with 15-30% elastane for stretch, moisture-wicking modal for breathability, and reinforced power mesh for structural support—key for DD+ sizes needing durability without bulk.

When I work with clients, the first thing we discuss is not design, but fabric. I always tell them, a bra is only as good as its foundation. For full cup bras, especially for DD+ sizes, this means going beyond basic cotton. We look for blends that offer a specific balance. For example, a high-quality modal blend provides softness and excellent moisture-wicking, which is crucial for comfort throughout the day. Then, we need serious support. This is where power mesh, with its unique structure, comes in. I always push for at least 15-30% elastane in our main fabrics to ensure the bra maintains its shape and support over time. We also conduct rigorous testing—fabric stretch recovery, for instance, must show 95%+ rebound after 5,000 cycles. We simulate real-world wear to make sure the fabric won't lose its integrity after countless washes. For specialty items like nursing bras, we integrate features like antimicrobial finishes directly into the fabric selection process to meet those specific needs.

Designing with Flexibility: Customizable Features for Brand Identity and Fit?

Generic full cups alienate customers. Customization—from strap placements to hook configurations—creates brand loyalty.

Offer adjustable wing heights, convertible straps, and 3-5 row hook options. These tweaks accommodate diverse body shapes while letting brands differentiate their designs.

I've seen firsthand how small design details can make a huge difference in customer satisfaction. One time, a client wanted a full cup bra that could also cater to women who often wear tank tops or racerback styles. We worked together to implement convertible straps, allowing the bra to be worn in multiple ways, greatly increasing its versatility. Another common issue is finding the right fit for different torso lengths. This is why adjustable wing heights are so important. We also offer a range of hook-and-eye closures, from three hooks for smaller bands to five for larger sizes, ensuring a secure and comfortable fit. Our process involves creating modular design elements, like different underwire casing options, which allows our clients to mix and match features. I remember a project for a major retailer where we introduced side sling modifications based on initial fit feedback. This simple design change significantly reduced returns and boosted positive reviews for their plus-size line.

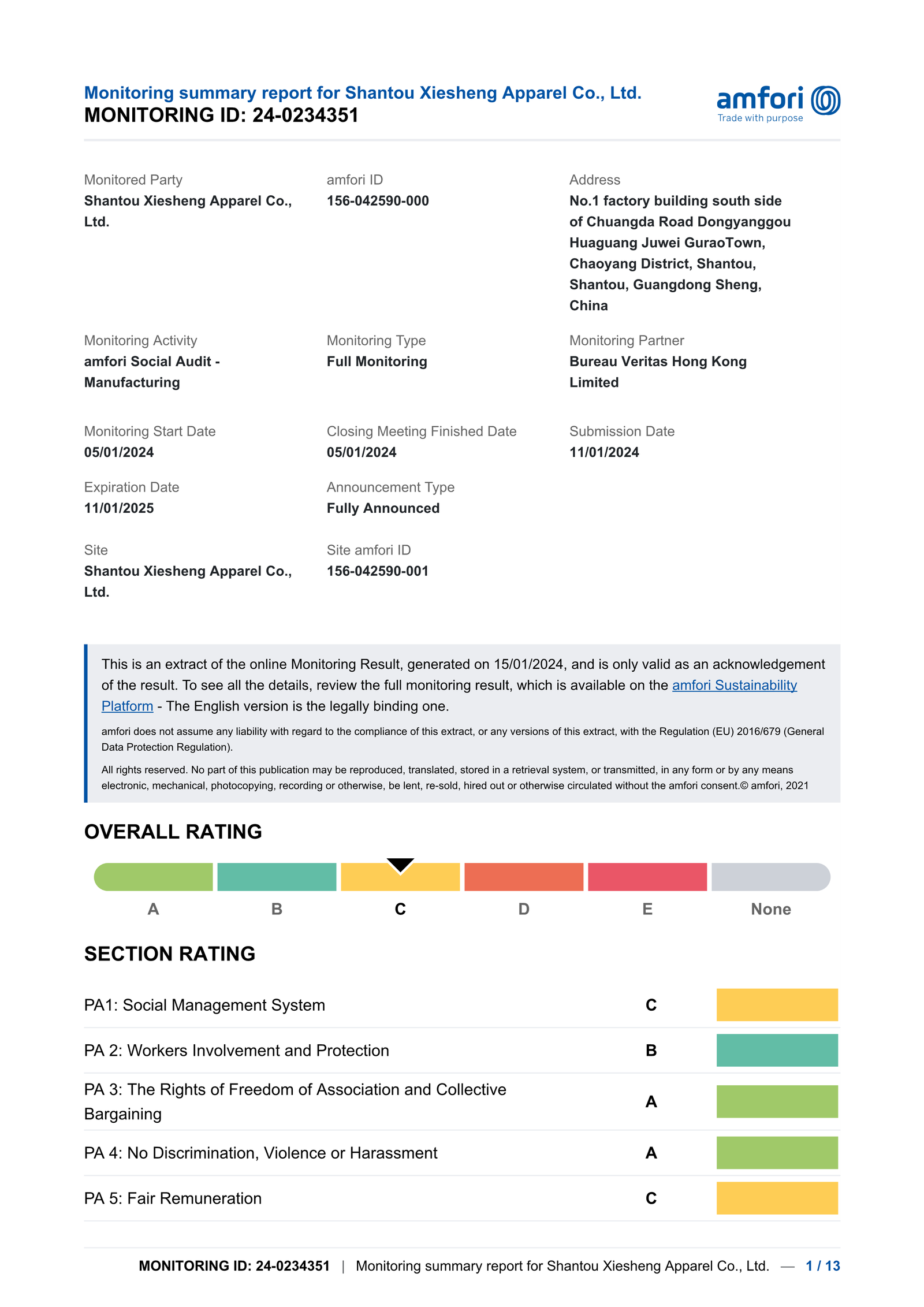

Compliance Ready: Certifications and Standards for International Markets?

Aesthetics won’t matter if bras are blocked at customs. Compliance is non-negotiable for global buyers.

Target markets dictate certifications: BSCI for EU social accountability, OEKO-TEX® for chemical safety, and FDA-compliant dyes for US medical-grade products like post-surgery bras.

When we talk about selling intimate apparel globally, I emphasize that compliance is as crucial as comfort. I once had a client who almost faced a major shipment delay because they overlooked a specific chemical restriction for their target European market. Luckily, my team, with our dedicated QC staff of over 10 people, caught it during our pre-production checks. This is why having certifications like BSCI and ISO isn't just a badge for us; they represent our commitment to ethical production and product safety standards. For instance, for our European clients, we always ensure that fabrics and components meet REACH regulations for chemical substances and that our manufacturing processes align with BSCI for social responsibility. For products destined for the US, particularly those in the medical or sensitive skin categories, we pay close attention to FDA-compliant dyes and materials. Our QC team, which frequently audits our 20+ sub-factories, even conducts surprise checks to verify adherence to these detailed standards.

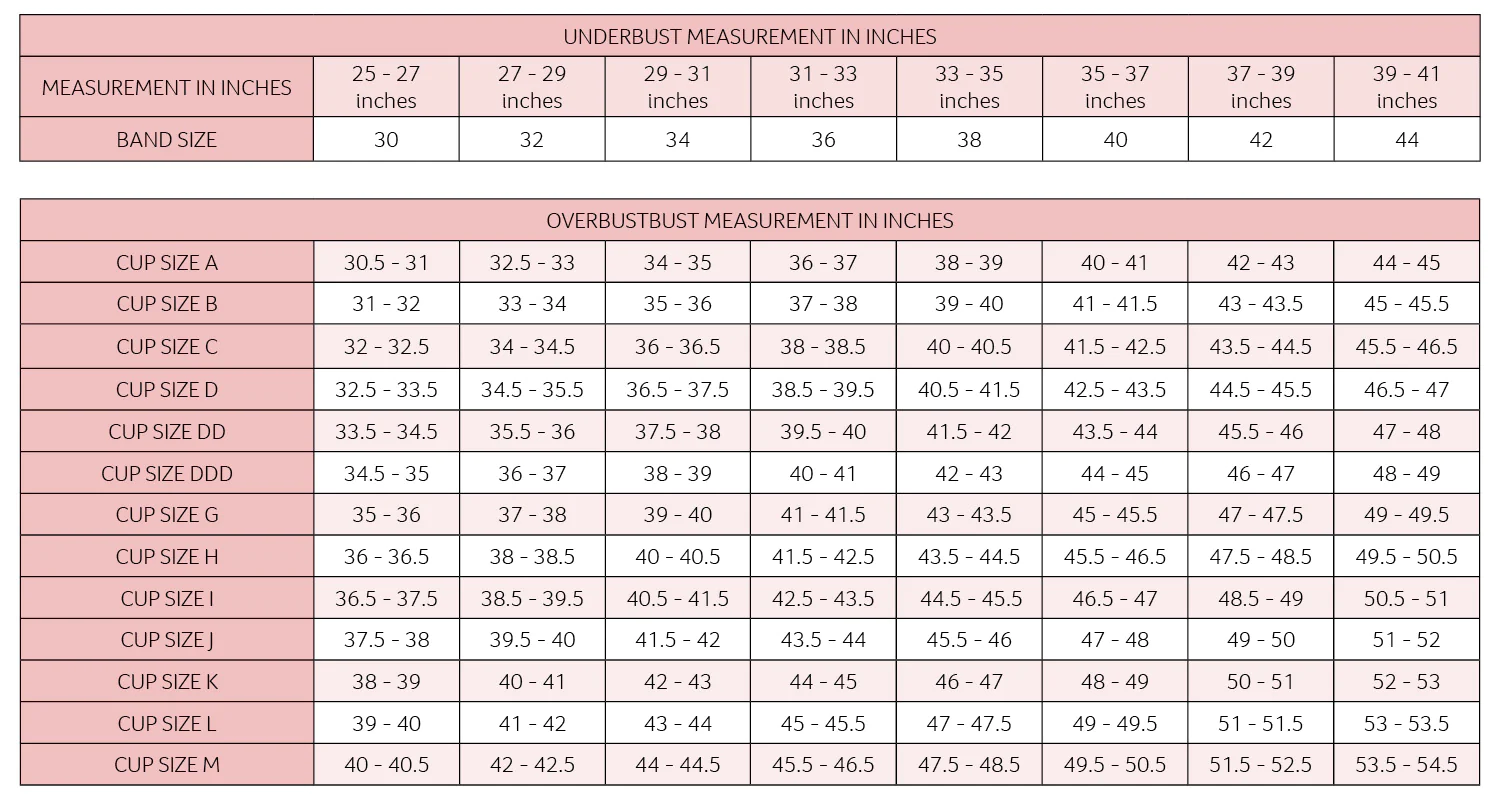

Precision Sizing: Grading for Full Cup Fit Across Body Types?

Sizing charts lie. Real precision? It’s about data-driven grading and real-wear tests.

Full cup grading needs separate algorithms for band/cup ratios. We use 3D fitting scans and wear trials across BMI ranges to adjust apex positioning and wing curvature.

I've learned that sizing a full cup bra is never a one-size-fits-all situation. It's a complex science where small adjustments can make a world of difference. For full cup bras, standard grading rules just don't cut it. You can't simply scale up a B-cup pattern and expect it to fit an H-cup comfortably. We employ specialized grading techniques that account for the unique proportions of DD+ busts, including different band-to-cup ratios. For instance, a 34D and a 38D will have entirely different fit profiles. My team uses 3D body scanning technology to capture precise measurements, which informs our pattern adjustments. We also conduct extensive wear trials with fit models across a wide range of body types and BMIs. This allows us to fine-tune critical elements like the apex positioning, which affects nipple coverage and projection, and the curvature of the bra wings, ensuring they sit flush against the body without digging in or gapping. One client had an issue with their full cup bras for petite figures—the straps were too wide-set and kept slipping. By working on a specific revised grading for petite full cups, we resolved the issue, making their customers much happier.

Proactive QA and Communication: Building Strong B2B Partnerships?

The best specs fail without transparency. Real partnerships thrive on proactive problem-solving.

Weekly video audits, pre-shipment fit videos, and dedicated CS portals cut revision cycles by 40%. We assign single-point contacts for each brand to streamline decisions.

In my experience, even with perfect designs and materials, without strong communication, a project can derail quickly. I learned this early on when a small miscommunication about a lace trim color nearly delayed a large order for an American client. Since then, I've prioritized building highly transparent communication channels. We now host weekly video calls with our clients, actively showing them progress and addressing any issues in real-time. This includes sharing detailed photos and videos of fabric inspections, stitching stages, and final packing. For critical milestones, we even offer pre-shipment fit videos, where we show the actual product on a fit model, so clients can approve the final look before it leaves our factory. We also assign a dedicated customer service representative to each brand. This single point of contact means faster decision-making and fewer misunderstandings. For one of our long-standing customers, we were able to catch a minor stitching error on a new bra style through a live video quality check. This saved them weeks of potential rework and kept their launch on schedule.

Conclusion

Full cup sourcing succeeds when technical rigor meets collaborative flexibility—prioritize fabrics, fit, compliance, and communication equally.