Ensuring Compliance and Certification in Lingerie Manufacturing: Building Trust in Global Trade

Is our lingerie safe and ethical? We follow all the rules.

We build trust in global trade by ensuring compliance and certification in lingerie manufacturing. This includes understanding international standards, guaranteeing material and fabric compliance for safety and quality, conducting process audits and factory certifications, documenting traceability, and maintaining ongoing monitoring and communication with clients.

I know that in today's world, it is not enough to just make good products. For us, at XIESHENG, we must also make them the right way. This means following many rules. It means getting important certifications. My factory, XIESHENG, is in Gurao town. We have qualifications like BSCI and ISO. These are not just papers. They show our commitment. They prove that we care about our workers. They prove that we care about the quality of our products. When we work with partners, they need to know all these things. They need to trust us. This trust comes from showing them that we meet all international standards. This transparency helps everyone. It reduces risks. It makes sure that our lingerie, whether it is period panties or a plus-size bra set, is not just beautiful. It is also ethically made and safe. This focus ensures strong, lasting relationships in global trade.

Understanding International Standards and Regulations

What rules do we follow for making lingerie? We know them all.

Understanding international standards and regulations involves continuous research into global textile safety and environmental protection regulationssafety, guidelines, and ethical manufacturing requirements, ensuring that all lingerie products comply with health, environmental, and social responsibility benchmarks in every target market.

The world of lingerie trade is complex. Every country, every region, has its own set of rules. As a lingerie manufacturer , I must know these rules very well. We track international standards. These include safety standards for fabrics. They include rules about chemicals that can be used. They also include ethical rules for how workers are treated. For instance, making tennager intimate underwear means we must be extra careful about skin-friendly materials. Nursing bras also have strict requirements for safety and hygiene. My team keeps up with these changes. We read reports. We attend seminars. This continuous learning helps us make sure that our products meet the standards of any market our partners sell to. This understanding is key. It prevents problems before they even start. It protects our partners' brands and their customers.

Material and Fabric Compliance: Guaranteeing Safety and Quality

Are our fabrics and materials safe? We check everything carefully.

Material and fabric compliance guarantees safety and quality by rigorously testing raw materials for harmful substances, confirming they meet international textile standards, and ensuring they are suitable for intimate apparel, thereby protecting consumers and upholding brand integrity.

For intimate apparel, what touches the skin is very important. The materials we use must be safe. They must be of high quality. We have strict checks for all our fabrics and materials. Before we use any fabric, it goes through testing. We test for harmful chemicals. We test for colorfastness. This means the color will not bleed onto the skin or other clothes. This is especially important for items like sexy lingerie or active shapewear, where direct skin contact is constant. Our professional QC team, with more than 10 persons, makes sure these tests happen. They check that the fabric meets specific requirements. For example, the fabric for period panties needs to be absorbent and breathable. The material for plus-size bra sets needs to offer strong support without irritation. This careful checking of materials is a major part of our quality promise. It ensures that the finished product is both safe and comfortable for the end-user.

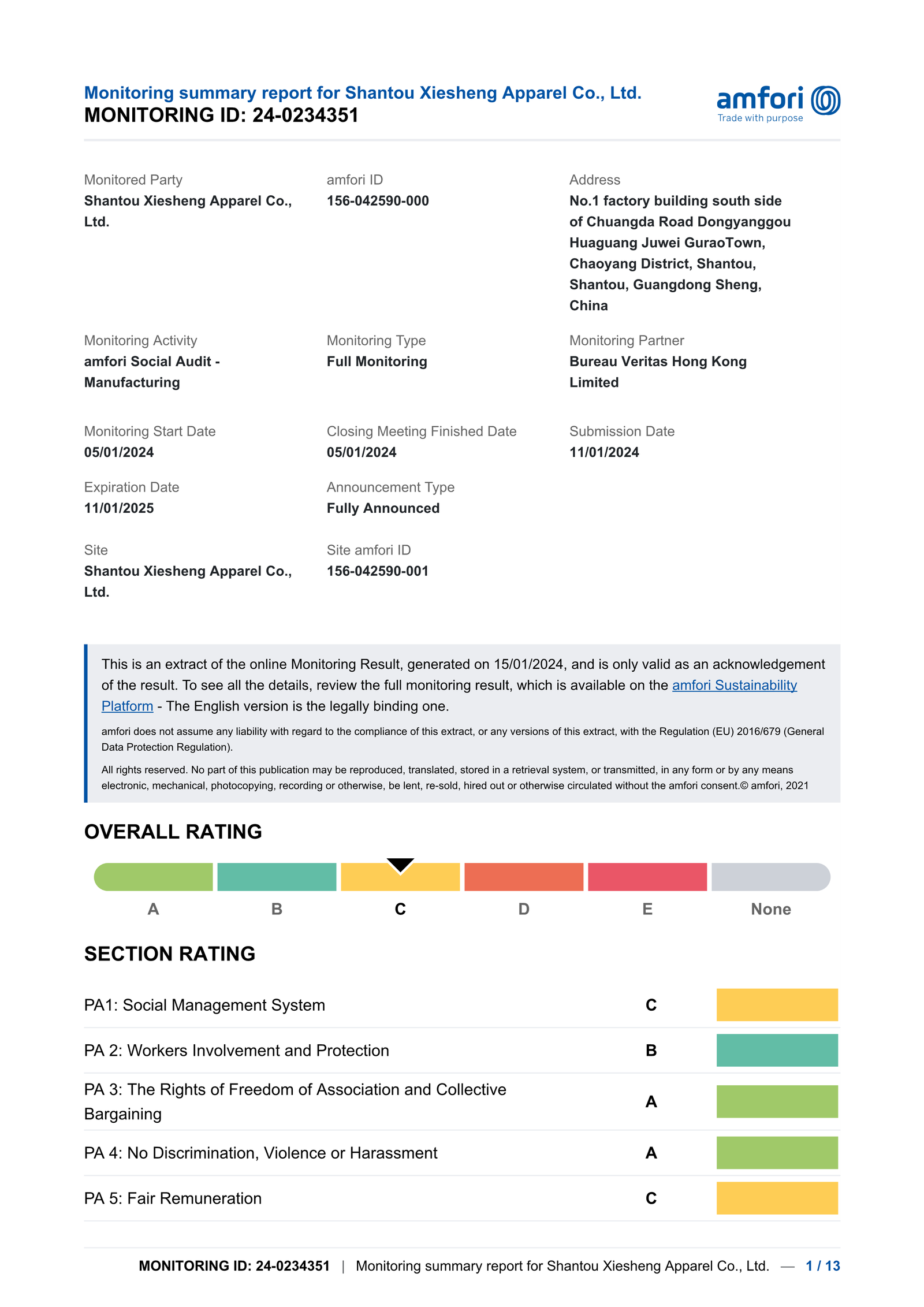

Process Audits and Factory Certification

How do we know our factory follows the rules? We get audited.

Process audits and factory certification demonstrate adherence to established guidelines by undergoing regular inspections of manufacturing procedures, labor practices, and quality management systems by independent bodies, verifying that operations meet international ethical and quality standards like BSCI and ISO.

Having certifications like BSCI and ISO is a promise. It is a promise that our factory operates under high standards. BSCI focuses on ethical labor practices. It means we treat our workers fairly. We have good working conditions. With over 300 workers and 10000 sqm of space, managing this well is important. ISO focuses on quality management. It means we have clear systems for making sure our products are consistent and good. To get these certifications, we go through regular audits. Independent groups come to our factory. They check everything. They look at our processes. They talk to our workers. They check our documents. They make sure we are following all the rules. These audits are like report cards for our factory. They help us improve. They also give our partners proof that we are a responsible and reliable manufacturer.

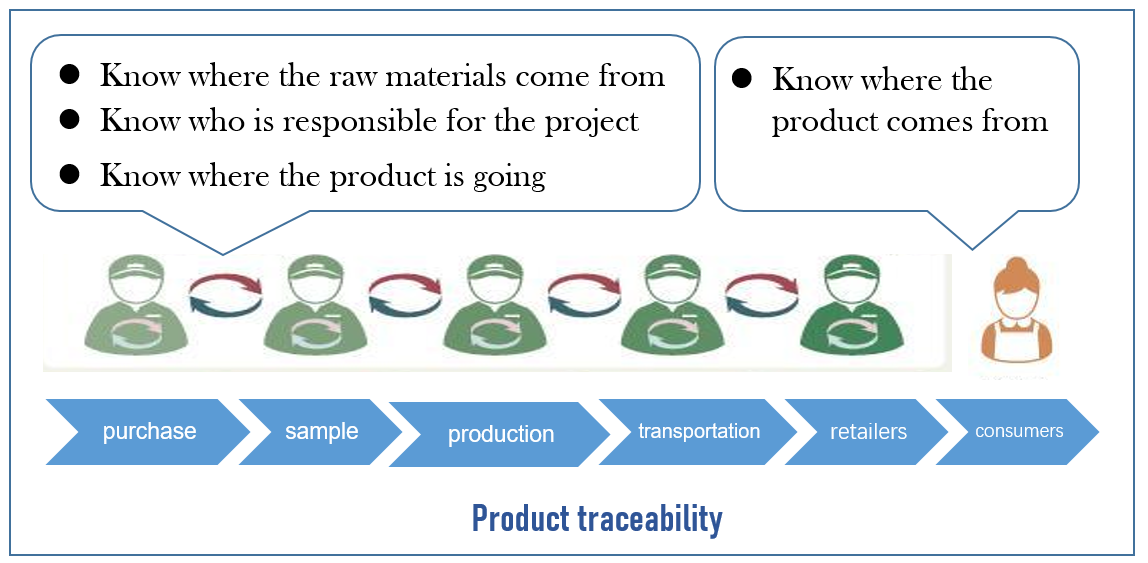

Documentation and Traceability for Transparent Transactions

Can we track every part of our product? Yes, we can.

Documentation and traceability for transparent transactions involve meticulously recording every step of the manufacturing process, from raw material sourcing to final shipment, enabling quick identification of product origins, components, and compliance status for full accountability and trust.

In global trade, trust is key. Transparency builds trust. That is why we keep very good records. We document everything. This means we can trace every part of our lingerie products. We know where the yarn comes from, we know where the fabric is sourced from, and we know who is in charge of the project, we can look up its history. For example, if a partner needs to know the exact composition of a fabric used in a daily fashion bra set from last year, we can provide that information. This system helps us with quality control. It helps us with compliance checks. It also helps our partners. They can give their customers detailed information about their products. This full traceability shows that we have nothing to hide. It makes transactions clear and open. It strengthens our relationships with clients.

Ongoing Monitoring and Supplier-Client Communication

Are we always getting better? We stay in touch and keep learning.

Ongoing monitoring and supplier-client communication involve continuous review of compliance requirements, proactive sharing of updates on standards, and maintaining open channels for feedback and collaboration, ensuring sustained adherence to regulations and fostering long-term cooperative relationships.

The world changes. Rules change. So, our work on compliance is never truly finished. We continuously monitor new regulations. We look for new best practices. My team makes sure we stay updated. We also believe in constant communication with our partners. We do not just make a product and then disappear. We keep in touch. We share updates on new textile standards. We inform them about any changes in certifications. We also listen to their feedback very closely. For example, if a partner selling in a new market alerts us to a specific local regulation for nursing bras, we investigate it. We work together to meet that requirement. This ongoing dialogue is vital. It means we can adapt quickly. It means we can keep improving our products and our processes. This proactive approach strengthens our partnerships and ensures long-term success for everyone involved.

Conclusion

Compliance and certification, through understanding standards, material safety, audits, traceability, and communication, are vital for building trust in global lingerie trade.