Seamless Underwear in the B2B Market: Unlocking Customization and Scaling Opportunities?

Are you struggling with the high costs, fabric waste, and slow lead times of traditional cut-and-sew manufacturing? This outdated process is limiting your ability to meet modern consumer demands for comfort.So how do we avoid the above problems?

Yes,seamless technology is a good solution. It uses advanced knitting to create garments with minimal seams, which cuts labor costs, reduces waste, and allows for incredible customization with faster production.

I remember when we first invested in our Italian Santoni machines. Some of my older, more traditional colleagues were skeptical. They were experts in cut-and-sew, a craft that has been around for centuries. But when I showed them how we could produce a nearly finished garment directly from a cone of yarn in just a few minutes, they understood. This wasn't just a new way to make underwear; it was a way to solve our B2B partners' biggest problems: speed, cost, and the growing demand for ultimate comfort. This technology gives brands a powerful competitive edge, and understanding how it works is key to leveraging it.

Why Is Seamless Underwear Revolutionizing Intimate Apparel Through Comfort and Fit?

Are you tired of customer complaints about scratchy seams and visible panty lines? Traditional underwear often fails to deliver the smooth, second-skin feel that modern consumers expect.

Seamless underwear is revolutionary because its tubular, stitch-free construction eliminates irritating seams. It stretches 360 degrees to perfectly conform to the body, providing an invisible, 'second-skin' fit that is unbelievably comfortable.

The secret to seamless comfort lies in its unique construction. Unlike traditional garments that are pieced together from multiple cuts of fabric, a seamless item is knit in a continuous tube. This process completely eliminates side seams, which are the number one cause of skin irritation and chafing.

The Science of a 'Second-Skin' Fit

The high-quality nylon and spandex blend we use allows the fabric to stretch in all directions—we call this 360-degree stretch. This means the garment moves with the body, adapting to every curve without digging in at the waist or leg openings. It feels less like you are wearing underwear and more like you have on a soft, supportive second skin. This adaptability is what creates such a superior fit across different body types and why it has become the gold standard for all-day comfort.

From Yarn to Garment: What is the Real Manufacturing Workflow of Seamless Underwear?

Are you confused about how seamless garments are actually made? This lack of understanding can make it difficult to source effectively and control the quality of your product line.

The workflow starts with programming a digital design file into a circular knitting machine. The machine then knits a complete 'tube' of the garment from yarn, which is then dyed, finished, and boarded into shape.

The seamless manufacturing process is highly technical and efficient, with far fewer steps than traditional cut-and-sew methods. It's a journey from digital code to a physical product. Here’s a simplified breakdown:

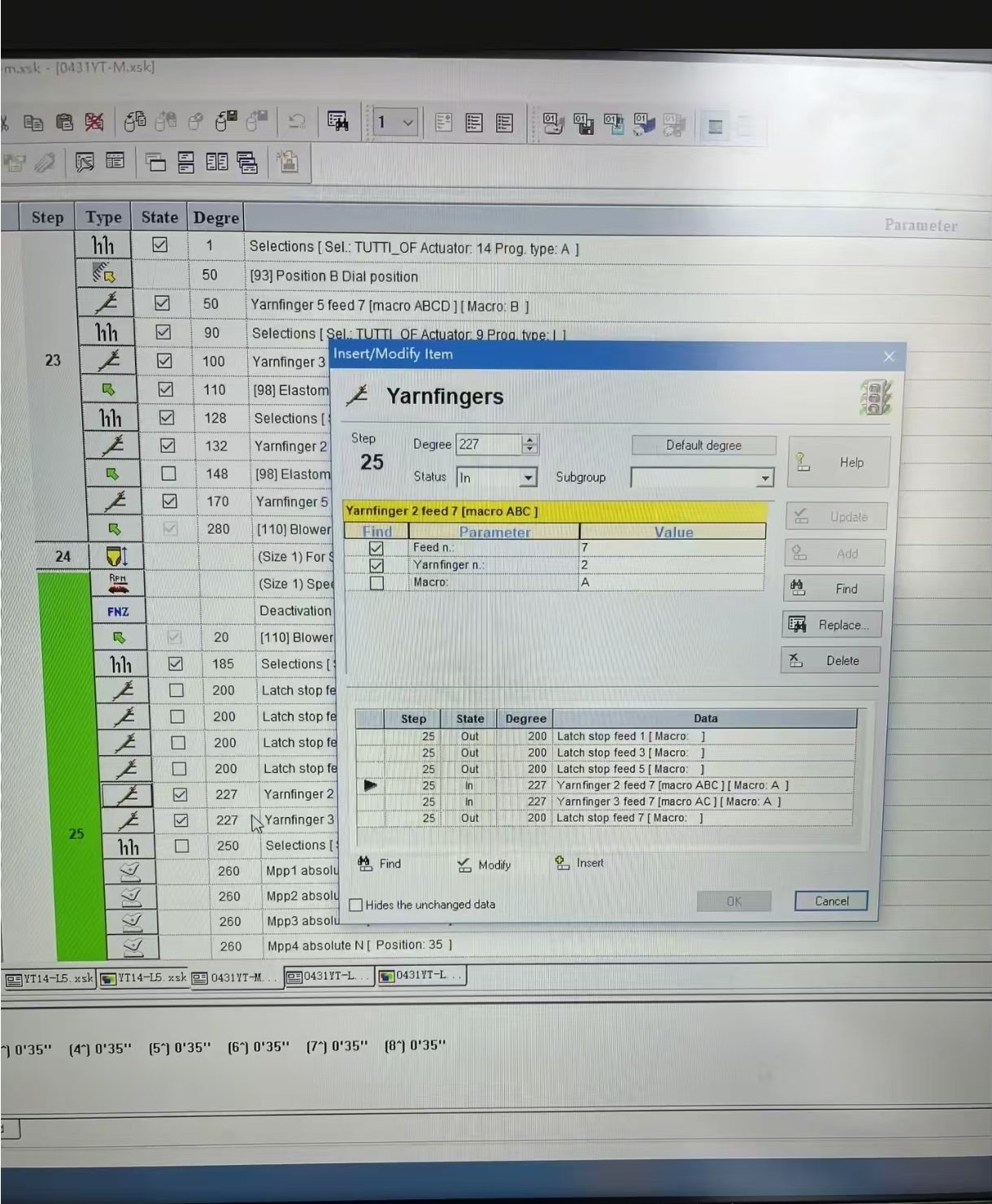

- Design & Programming: Our technicians take your design and convert it into a digital program. This file controls every single stitch, texture, and pattern.

- Knitting: The program is loaded onto a Santoni machine. Cones of yarn are fed into the machine, and it knits the garment in a tubular shape at high speed. A brief or bralette can be produced in just a few minutes.

- Finishing: The knitted tubes may require minimal finishing, like sewing in a cotton gusset for briefs or attaching straps for a bralette.

- Dyeing & Boarding: The garments are then dyed. After dyeing, they are placed on heated metal forms, a process called boarding, which sets them into their final shape and size.

| Manufacturing Step | Traditional Cut-and-Sew | Modern Seamless |

|---|---|---|

| Patterning | Multiple physical patterns | Single digital file |

| Cutting | Labor-intensive, high fabric waste | No cutting, almost zero waste |

| Sewing | Many seams, many workers | Minimal, often just one or two steps |

| Lead Time | Longer | Significantly Shorter |

Are Certifications and Sustainability Important in Seamless Underwear Production?

Are you concerned about factory ethics and fabric safety? Today's educated consumer will abandon brands that cannot prove their products are safe to wear and made responsibly.

Yes, they are critical. Certifications like OEKO-TEX® assure customers the fabric is free from harmful chemicals. The seamless process is also inherently more sustainable, creating less fabric waste and using less energy.

In today’s B2B market, how you make something is just as important as what you make. For intimate apparel that sits against the skin all day, product safety is non-negotiable. That's why we ensure our materials are certified to OEKO-TEX® Standard 100. This certification guarantees that every thread, button, and accessory has been tested for harmful substances and is safe for human health. It provides critical peace of mind for you and your end customer. Beyond safety, sustainability is a huge factor. Seamless production is a much greener process. In cut-and-sew, up to 20% of the fabric can be wasted as off-cuts during the cutting process. Our knitting machines create the garment to shape, reducing fabric waste to almost zero. This efficiency also means we use less energy, lowering the carbon footprint of every item we produce.

What Popular Product Categories Do B2B Buyers Actually Want in Seamless Intimates?

Are you not sure which seamless styles to add to your collection? Investing heavily in the wrong products can lead to unsold stock and a major financial loss for your business.

B2B buyers consistently want foundational styles. High-demand items include everyday briefs and thongs, comfortable bralettes and bandeau tops, and versatile light shapewear like control shorts and camisoles that smooth without constriction.

While seamless technology can be used for many things, B2B buyers find the most success by focusing on core categories that directly solve a customer's problems. Here are the clear winners:

- Everyday Underwear: This is the biggest category. Styles like briefs, hipsters, and thongs are top sellers because they solve the problem of Visible Panty Lines (VPL) under clothing.

- Comfort Bras & Bralettes: The demand for wire-free comfort is huge. Seamless bralettes and bandeau tops offer light support and a smooth shape without any digging wires or hooks.

- Light Shapewear: Consumers want smoothing, not C. Seamless technology is perfect for creating high-waisted briefs, shorts, and camisoles that gently shape the torso and thighs without the extreme compression of traditional shapewear.

These categories form the foundation of a profitable seamless program because they offer clear, tangible benefits that customers are actively searching for.

How Can You Balance Flexibility and Production Speed with Mass Customization in Seamless Underwear?

Do you believe offering custom designs must mean slow production and high MOQs? This common assumption might be holding your brand back from its full creative and commercial potential.

Seamless technology makes this balance possible. Customizations like logos, textures, or mesh panels are programmed into the knitting machine. This allows for rapid design changes, enabling mass customization at high speed.

This is one of the most powerful features of seamless manufacturing for B2B brands. In a traditional factory, changing a design means creating new patterns and reconfiguring sewing lines, which is slow and expensive. With seamless, the design variation happens in the digital code. We can program the knitting machine to create an incredible range of features directly in the fabric. We can knit in a ribbed texture for a fashion look, create breathable mesh zones for activewear, knit a brand's logo directly into the waistband, or create areas of targeted compression for shapewear. The ability to make these changes digitally means we can produce many different variations and styles quickly and efficiently, often with a much lower MOQ per style than with cut-and-sew. This gives your brand the flexibility to test new ideas and offer a much wider variety of products to your customers.

Conclusion

Seamless underwear is the key to B2B success. It offers an ideal mix of production efficiency, deep customization, and the incredible comfort that modern consumers demand from their intimate apparel.