Seamless Underwear Customization: Driving B2B Growth and Market Fit

The apparel market is changing. Just selling standard underwear is not enough anymore. Buyers want products made just for them.

At my factory, XIESHENG, we know customization is key. We work with wholesalers, distributors, and brands. We offer flexible designs, clear quality checks, and good communication. This helps our partners meet what their customers need and grow their businesses.

I have seen the undergarment industry change a lot. Not long ago, factories just made large batches of basic underwear. Buyers cared mostly about price and speed. Today, that has changed. My customers, whether they are big retailers like Walmart or smaller undergarment shops, want more. They tell me their own customers ask for specific features. They want unique styles. They need proof that products are safe and made well. This means we, as manufacturers, must offer more than just bulk production. We must offer customization. We have to adapt to specific brand needs. We need to show clear quality. We need to talk openly. This is how we help our B2B partners succeed. It is how we help them find their place in a busy market. This approach helps us all grow together.

High-Performance Yarns: Building Comfort, Elasticity, and Durability

Are you still using basic threads for seamless underwear? Simple yarns might seem cheap, but they will not please customers over time.

We use high-quality yarns. These threads make seamless underwear comfortable. They help it stretch well. They make it last a long time. This gives end-users a great experience every time.

Choosing the right yarn is very important for seamless underwear. It affects everything about the product. It decides how the underwear feels against the skin. It also impacts how long the garment will last. And it determines what specific things the underwear can do. For example, some yarns are great at moving sweat away from the body. Others can keep their shape well, even after many washes. We pick our fibers very carefully. We use special blends. These include soft, breathable bamboo. We also use strong, moisture-wicking nylons. These choices mean our products offer both comfort and good performance. My experience working with brands like Ashley shows that good quality yarns are a major selling point. Customers want soft feelings. They need yarns that do not create little fuzz balls. They need elastic that keeps its stretch. We test every yarn we get. We check its strength. We check how much it can stretch. We make sure it meets our high standards. This process ensures the finished underwear is not just seamless, but also works really well and lasts a long time.

Adaptable Customization: Meeting Brand-Specific Demands

Do you think one design fits every market? Not offering custom options means your brand risks blending in, losing its unique voice.

We offer many choices for styles, colors, and features. This allows each brand to create unique seamless underwear. We help them stand out to their own customers.

Customization is a big part of what we do at XIESHENG. My team understands that every brand has a unique story. They have different target customers. So, we offer very flexible options. For example, brands can ask for specific waist heights. They can choose different leg openings. They can pick special colors that match their brand palette. We can also integrate unique functional elements. This includes different support levels for nursing bras. Or varied compression zones for shapewear. One time, a customer needed a very specific shade of blue for their teenage underwear line. It involved working closely with our dye house to match the exact Pantone code. This level of detail helps our OEM partners build their distinct brand identity. It also allows wholesalers to offer a broader, more appealing range of products. My factory has the machines and the skills to make these detailed customizations a reality for our partners. This ensures their products truly reflect their brand vision.

Certifications and Compliance: Strengthening Global Market Access

Are you ignoring international standards and certifications? Without the right documents, your products may not reach new customers overseas.

We hold important certifications like BSCI and ISO. These prove our quality and ethical practices. This helps our buyers sell our products worldwide without problems.

In the global market, certifications are absolutely necessary. They are not just nice to have. They open doors to new markets. They build trust with consumers. At XIESHENG, we know this well. Our BSCI certification shows our commitment to fair labor practices. This is crucial for brands that sell in ethical-conscious markets. Our ISO certifications confirm our strong quality management systems. This means our production processes are reliable. It means our products are consistent. I have seen many times how these certificates help our customers. For instance, a buyer for Walmart needs to ensure that their suppliers meet strict factory audit standards. Our records help them pass these checks easily. Another time, a European distributor needed proof that our fabrics were free of harmful chemicals for their premium line. Our existing compliance reports quickly solved their concern. These official documents give our partners confidence. They help them expand their reach. They prevent delays in customs and sales.

Precision Sizing and Fit: Addressing Diverse Consumer Segments

Do your seamless garments frequently get returned because of bad fit? Poor sizing causes frustration and lost sales, especially in online shopping.

We focus on precise sizing for seamless underwear. We use detailed measurements and real-person fit testing. This helps ensure a comfortable and accurate fit for many body types.

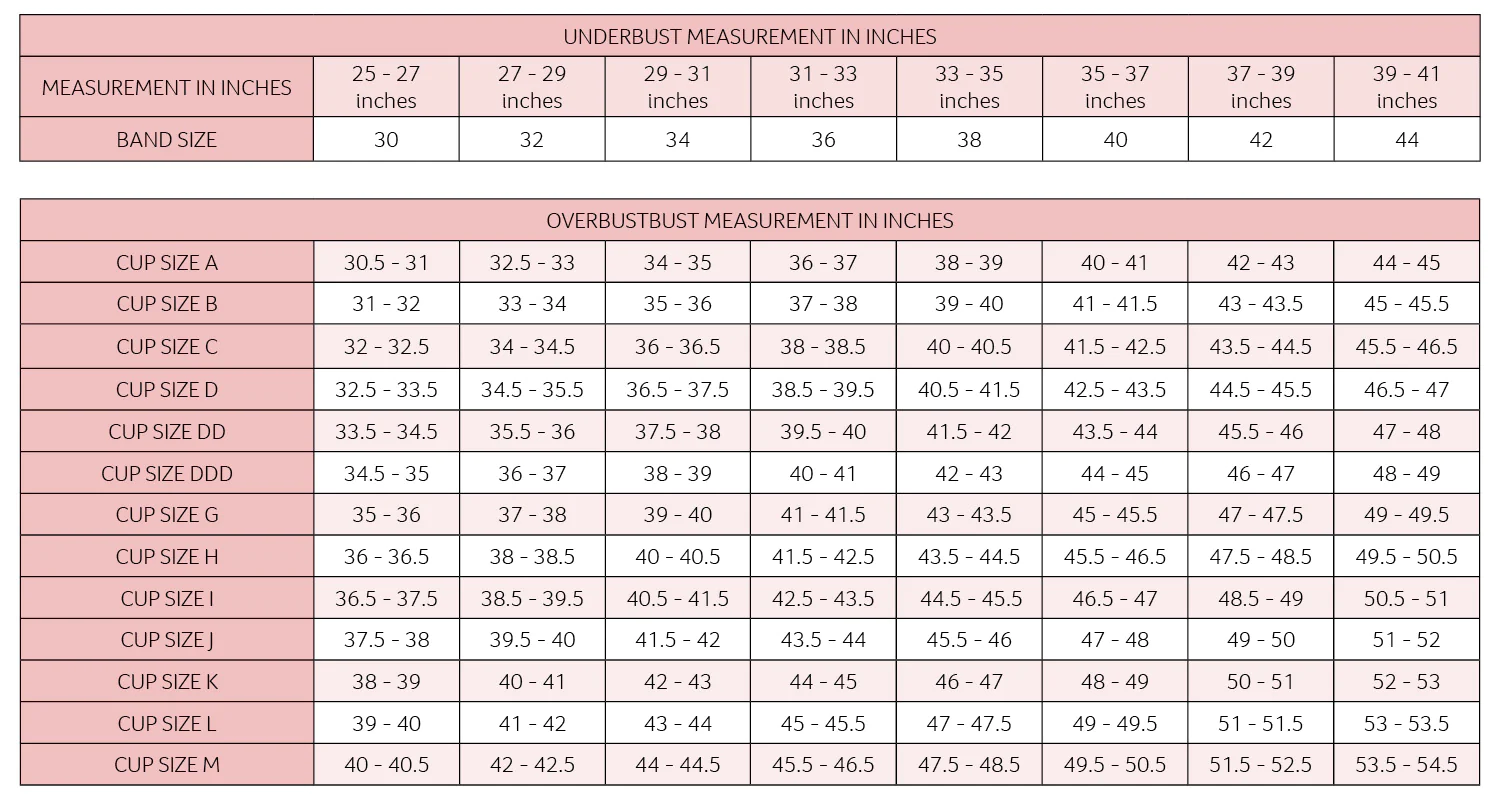

Getting the fit right is vital for seamless underwear. Unlike traditional clothing, seamless garments rely on stretch and knitting patterns for their shape. If the sizing is off, the garment will not fulfill its purpose. It might roll. It might sag. It might feel too tight. My team and I put a lot of effort into this. We create detailed size charts. These charts consider various body shapes and sizes. We use specific measurements for different regions. For example, Asian sizing can vary from European sizing. We also perform rigorous fit tests. We use fit models with various body types. This helps us see how the garment behaves when worn. It allows us to make adjustments. We make sure our plus size bra sets offer both comfort and support. We ensure our period panties provide a secure, leak-proof fit. This attention to detail reduces returns for our clients. It also builds customer loyalty. Happy customers who find a perfect fit will come back for more.

Effective Communication and Quality Checks: Enhancing Supplier–Buyer Trust

Are you facing delays or surprises from your manufacturers? Lack of clear talk and proper checks can damage trust and cause big problems in production.

We talk clearly and often with our buyers. Our strong quality control team checks products at every step. This makes sure our partners are always informed and receive top-quality goods.

At XIESHENG, I believe strong business relationships are built on clear communication and solid quality control. We do not just wait for problems to arise. We actively keep our partners in the loop. From the moment an order is placed, we provide regular updates. This includes updates on fabric arrival. It covers production progress. It also notes shipping schedules. My team of over 10 experienced QC professionals is involved at every stage. They perform checks on raw materials. They monitor the knitting process. They meticulously inspect finished garments. They even oversee packaging. For example, during a large order for KIK, our team found a slight color variation in one batch of fabric. We immediately informed KIK, offering solutions and explaining the steps we would take to fix it. This transparency built even more trust. It showed them we value their business. It is this proactive communication and thorough quality check system that strengthens our partnerships with all our clients, ensuring mutual success.

Conclusion

Customization in seamless underwear is a must for growth. It means using good fabrics, flexible designs, certified quality, accurate sizing, and clear communication. These elements help build strong partnerships.