How can your brand work smoothly with ODM/OEM lingerie factories to make your own custom designs? It's about knowing the step-by-step process.

Navigating OEM/ODM collaboration for your lingerie brand means clearly defining your vision, choosing the right manufacturing partner, working closely on design and development, prioritizing strict quality control, and aligning on costs, lead times, and compliance to successfully bring your custom intimate apparel to market.

I know that for you, as a lingerie brand owner, bringing your unique designs to life requires a special kind of partnership. You have a unique vision for your intimate apparel brand. You need a manufacturer who can turn those ideas into high-quality, customizable products that meet your customers' needs. This is where OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) collaborations come in. At XIESHENG, we specialize in helping brands like yours. This guide will walk you through the essential steps for a successful OEM/ODM collaboration, helping your brand shine in the competitive intimate apparel market.

Select the Right OEM/ODM Partner

How do you pick the best factory to make your special lingerie designs? You need to choose carefully.

Selecting the right OEM/ODM partner means you, as a lingerie brand, must find a manufacturer with proven expertise in your product type, sufficient production capacity, strong quality control, ethical certifications like BSCI/ISO, and the willingness to collaborate closely to turn your unique designs for items into reality.

Choosing the right manufacturing partner is perhaps the most critical step for your lingerie brand. It is like choosing a co-pilot for your journey. You are looking for more than just a factory; you are looking for a true collaborator. When evaluating potential OEM/ODM partners, consider a few key factors. Does the manufacturer have category-specific experience, hold international certifications, guarantee quality, meet your capacity needs, and communicate effectively? For instance, XIESHENG

specializes in diverse items, from everyday fashion bra sets to specialized period panties.With over 20 years of lingerie manufacturing experience—combined with ODM/OEM expertise, a skilled workforce, efficient production capacity, Professional communication and quality inspection team and successful collaborations with leading international brands—we can confidently serve your lingerie brand. In addition, we hold BSCI1 and ISO certifications2, and we have consistently upheld our commitment to ethics and environmental protection.

State your requirements clearly to your ODM/OEM partner

What do you need to do first to make your lingerie brand's ideas real? Clearly explain what you want.

Defining your brand vision and requirements is the crucial first step in any OEM/ODM collaboration. You need to clearly articulate your lingerie product's design aesthetic, target market, specific features, material preferences, and desired quality standards to accurately communicate your needs to your manufacturing partners.

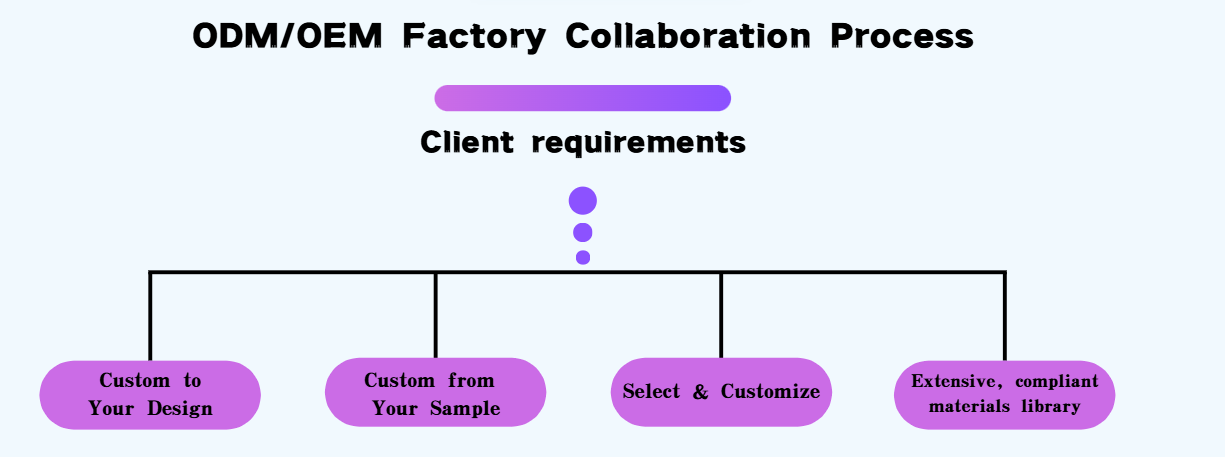

Before you even talk to a manufacturer, you need to be crystal clear about what your brand stands for. As a brand owner, your vision is your compass. For example: What type of underwear do you want to produce? Who is your target market? Which styles, colors, and sizes should the collection include? In this process, you need to provide detailed specifications. This includes sketches, technical drawings, material choices (like specific types of lace or organic cotton), color palettes, sizing requirements, and any functional features (like special clasps for nursing bras). If you want to launch new products quickly, reduce proofing costs, or lack design resources, our factory can provide ready-made or customized designs, pattern libraries, and material solutions for you to select and fine-tune.The more precise you are at this stage, the easier it will be for us, as an OEM/ODM manufacturer, to understand and fulfill your vision. This clarity prevents misunderstandings down the line and ensures that the final lingerie product truly represents your brand.

Co-Design & Development Workflow?

How do you work with the factory to make unique lingerie designs together? A good plan helps you build it.

The co-design and development workflow is where you, the lingerie brand, actively collaborate with the OEM/ODM partner's design and technical teams. This involves iterative sampling, material selection, pattern adjustments, and fit testing to refine your vision into a production-ready intimate apparel product like a plus size bra set or sexy lingerie, ensuring both aesthetic appeal and functional performance.

Once you have chosen your OEM/ODM partner, the real creative work begins. This is the co-design and development workflow. As a brand, you will work closely with our designers and technical teams. We will take your initial sketches and turn them into technical drawings, then create physical prototypes. This stage involves a series of samples: It may start with a simple fabric and color sample, then move on to development sample, proto sample, revised sample, full-size sample, and finally pre-production sample. You will provide feedback on each iteration. For example, if you are developing a new shapewear line, you will test the compression, comfort, and seam placement. If it is a complex sexy lingerie piece, you will check the drape of the fabric and the intricate detailing. This back-and-forth process, refining patterns, selecting specific trims, and adjusting measurements, ensures that the final product meets your exact design and quality standards before mass production begins. It is an investment of time that pays off in a perfectly executed product.

Focus on Quality Control

How do you make sure every piece of lingerie comes out perfectly? You must focus very much on checking the quality.

Focusing on quality control throughout the OEM/ODM process is paramount for your lingerie brand. This means establishing clear quality benchmarks, conducting inspections at various production stages and working with a manufacturer that has a dedicated QC team to ensure consistent excellence.

For any brand, quality is non-negotiable. This is especially true for intimate apparel, where comfort, fit, and durability are paramount. As a brand owner, you must prioritize quality control throughout your OEM/ODM collaboration. This starts with clarifying your quality expectations upfront. What are your acceptable defect rates? What are the key performance indicators for your lingerie production item? Our factory, XIESHENG, has a professional QC team of more than 10 persons. They conduct inspections at every stage: incoming raw materials (for example, ensuring the lace for sexy lingerie meets your standards), in-process production (checking stitching, sizing), and final inspection after the undergarments are finished. You should also consider having your own quality checks or a third-party inspection at critical points. This rigorous attention to detail ensures that every item meets your brand's high standards and safeguards your reputation.

Cost, Lead-Time & Compliance Alignment

How do you make sure the money, timing, and rules all match up for your lingerie orders? Everything needs to align.

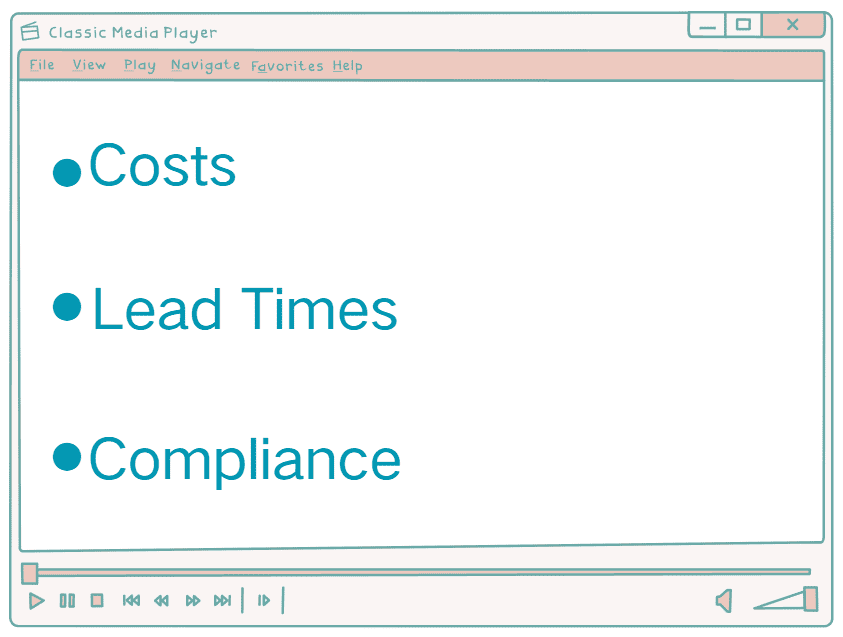

Aligning on cost, lead time, and compliance means you negotiate and confirm all financial aspects, production schedules, and regulatory requirements with your OEM/ODM partner. This ensures that your custom lingerie production, stays within budget, meets market deadlines, and adheres to all necessary ethical and quality standards, protecting your brand's integrity.

Finally, for a successful OEM/ODM collaboration, you need to ensure a clear alignment on costs, lead times, and compliance. As a brand, you have a budget. You need to confidently price your customized lingerie products for your target market. This means getting a transparent breakdown of manufacturing costs. Next, lead time is crucial for your seasonal collections. You need to know when your order will be ready to ship so you can plan your marketing and distribution. At XIESHENG, we provide clear estimates based on your order size and complexity. Lastly, compliance is non-negotiable. You need to ensure the manufacturer adheres to all relevant labor laws, environmental regulations, and quality certifications (like our BSCI and ISO). This protects your brand from reputational damage and legal issues. Clear communication and written agreements on these three pillars are essential. They ensure your specific intimate apparel products are delivered on time, within budget, and to the highest ethical and quality standards.

Conclusion

By partnering with a manufacturer like Xiesheng, clarifying your requirements, closely overseeing product design and development, and communicating proactively on cost, production schedules, and compliance, your brand can successfully launch a customized product.