Communicate with Confidence: How to Ensure Success in Your Intimate Apparel Orders?

How do you make sure your intimate apparel orders go smoothly? You communicate with confidence.

To ensure success in your intimate apparel orders, clarify product specifications, establish transparent communication channels, confirm samples and approvals at each stage, plan realistic timelines, and maintain post-order follow-up and feedback with your manufacturer.

I know that for any brand, placing an order for intimate apparel feels like a big step. It is full of hopes and expectations. As an undergarment manufacturer, we see how good communication makes all the difference. It turns potential problems into smooth processes. At XIESHENG, we believe that clear and confident communication is the backbone of every successful partnership. It helps us bring your vision for new period panties, nursing bras, or sexy lingerie to life exactly how you imagine it. This guide will walk you through the key steps. It will show you how to communicate effectively with your manufacturer. It ensures every order meets your standards and goes out on time.

Clarify Product Specifications Before Production?

How do you avoid mistakes in your order? Make sure every detail is crystal clear.

Clarifying product specifications before production involves providing manufacturers with detailed documentation including design sketches, material selections, sizing charts, color codes, and any specific construction requirements to ensure the final intimate apparel product matches your exact vision.

Before we even cut the first piece of fabric, it is essential that all product specifications are incredibly clear. This is the foundation of a successful order. I have seen many times how even small misunderstandings here can cause big issues later. You need to give us everything. This includes detailed design sketches. Also, specify the exact materials, like the type of lace for sexy lingerie or the fabric blend for shapewear. Provide precise sizing charts. Give us color codes, like Pantone numbers. Tell us about any specific construction requirements, such as stitch types or closure details for a plus-size bra set. The more information you provide, the better. This helps our team understand your vision perfectly. It ensures that what we produce is exactly what you expect. It saves time and avoids costly reworks down the line.

Establish Transparent Communication Channels with Your Manufacturer?

How do you keep things open and honest with your factory? Set up clear ways to talk.

Establishing transparent communication channels with your intimate apparel manufacturer means designating key contacts, agreeing on preferred communication methods (e.g., email, video calls), setting expectations for response times, and maintaining open dialogue for all inquiries and updates throughout the production cycle.

Good communication is not just about what you say. It is about how you say it and through what channels. For our partners, it is important to establish transparent communication channels from the very beginning. We recommend having a main point of contact on both sides. This person can handle all major discussions. Agree on the best ways to communicate. Is it email for detailed updates? Are video calls better for design reviews? We use these methods regularly. We make sure our sales team is always available. They provide timely responses. This open dialogue helps us address any questions or concerns quickly. For example, if there is a slight delay in a material shipment for a tennager intimate underwear order, we let you know immediately. This transparency builds trust. It ensures there are no surprises during the production process. It makes the whole experience much smoother.

Confirm Samples and Approvals at Each Stage?

How do you know your order is perfect as it goes along? Check and approve every step.

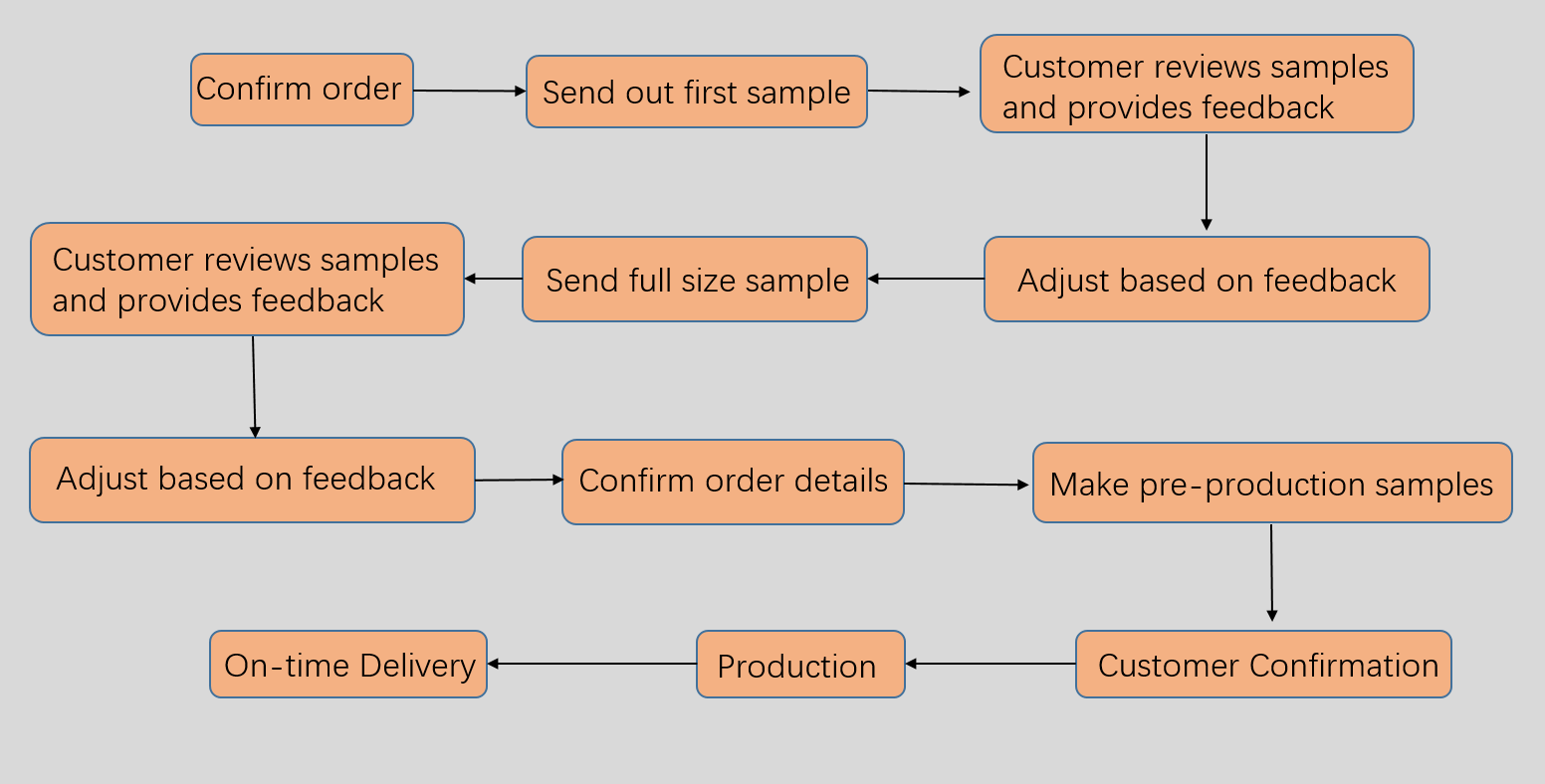

Confirming samples and approvals at each stage involves a meticulous review of prototypes, pre-production samples, and fit samples to ensure every detail of the intimate apparel meets your brand's standards before moving to bulk production, preventing errors and ensuring quality.

This step is critical for ensuring quality and accuracy. We never move to the next stage without your explicit approval. This means we make samples. You review them carefully. First, there might be a prototype. This shows the basic design. Then, a fit sample, especially important for items like bras or shapewear, to ensure proper sizing and comfort. Finally, a pre-production sample. This is essentially what your final product will look like. It uses the correct fabric, color, and trim. You need to check every detail. For example, for nursing bras, you would check the clasp function and ease of use. For daily fashion bra sets, you would check the strap adjusters and cup shape. Your approval at each of these stages is your green light for us. It confirms that we are on the right track. It helps prevent costly mistakes once bulk production begins.

Plan Realistic Timelines and Production Schedules?

How do you keep your orders on track? Set real-world dates and stick to them.

Planning realistic timelines and production schedules involves setting achievable deadlines for each stage of intimate apparel manufacturing, factoring in lead times for material sourcing, sampling, production, and shipping, while also accounting for potential unforeseen delays to ensure timely delivery.

Setting realistic expectations for timelines is absolutely vital. It is easy to want things fast. But rushing can lead to mistakes. We work with you to plan a production schedule that is achievable. This includes understanding lead times for materials. For example, if you need a specific type of fabric that is custom-dyed, it will naturally take longer. We factor in the time for sampling and your approval process. Then, actual production time. Finally, shipping. We also build in a little buffer for unexpected delays. Things like customs issues or a slight machinery breakdown can happen. For our established customers, we have refined this over time. We give transparent estimates. We communicate if there are any changes. This way, you can plan your inventory and marketing campaigns with confidence. Realistic planning prevents stress and ensures timely delivery of your intimate apparel.

Maintain Post-Order Follow-Up and Feedback?

How do you make sure future orders are even better? Keep talking after delivery.

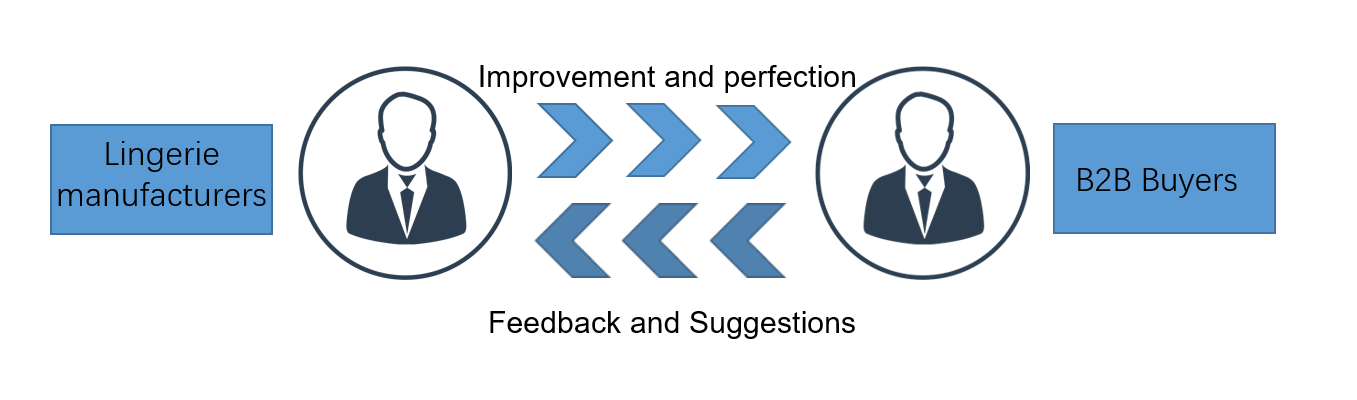

Maintaining post-order follow-up and feedback involves having a structured process to gather your insights on the delivered intimate apparel products, assessing overall satisfaction with the manufacturing process, and using this valuable information to refine future orders and strengthen the long-term partnership.

The relationship does not end once the order is shipped. In fact, post-order follow-up is crucial for continuous improvement. We always encourage our partners to give us feedback. What worked well? What could be better? We want to know your thoughts on the quality of the period panties, the fit of the shapewear, or the overall execution of your custom sexy lingerie line. This feedback is incredibly valuable to us. It helps us understand your needs better. It allows us to refine our processes. For example, if you notice a consistent comment from your customers about a certain fabric, we can explore alternatives for the next order. This ongoing dialogue shows our commitment to your brand's success. It ensures that each subsequent order is even more efficient and perfectly tailored to your expectations. It builds a strong, lasting partnership.

Conclusion

Successful intimate apparel orders stem from clear specifications, open communication, stage-by-stage approvals, realistic timelines, and continuous post-order feedback for ongoing improvement.