Full Body Bra Sourcing: Overcoming Challenges for B2B Success

Sourcing full body bras can be tricky. How do we make it easy for you?

Sourcing full body bras for B2B success means tackling challenges like ensuring accurate sizing for diverse markets, selecting the best materials, confirming manufacturer compliance, managing communication efficiently, and implementing strict quality control and sample testing.

I know that sourcing full body bras can present unique challenges for businesses. These items are more complex than standard bras or panties. They cover more of the body. They need to fit many different body shapes perfectly. They also need to be comfortable and supportive all day long. For us, at XIESHENG, we understand these difficulties. We have worked hard to build processes that overcome them. We want to make sure our B2B partners get the best product. We also want to make sure the sourcing process is smooth for them. This means thinking about every step. It means making sure we pay attention to key details. Our goal is to make full body bra sourcing a success for every client, every time.

Ensuring Accurate Sizing and Fit for Diverse Markets

How do we get the fit right for everyone, everywhere? Careful sizing is the key.

Ensuring accurate sizing and fit for diverse markets requires extensive pattern grading, careful consideration of various body shapes and proportions worldwide, and rigorous fit testing on different models to guarantee comfort, support, and a flattering silhouette for all customers.

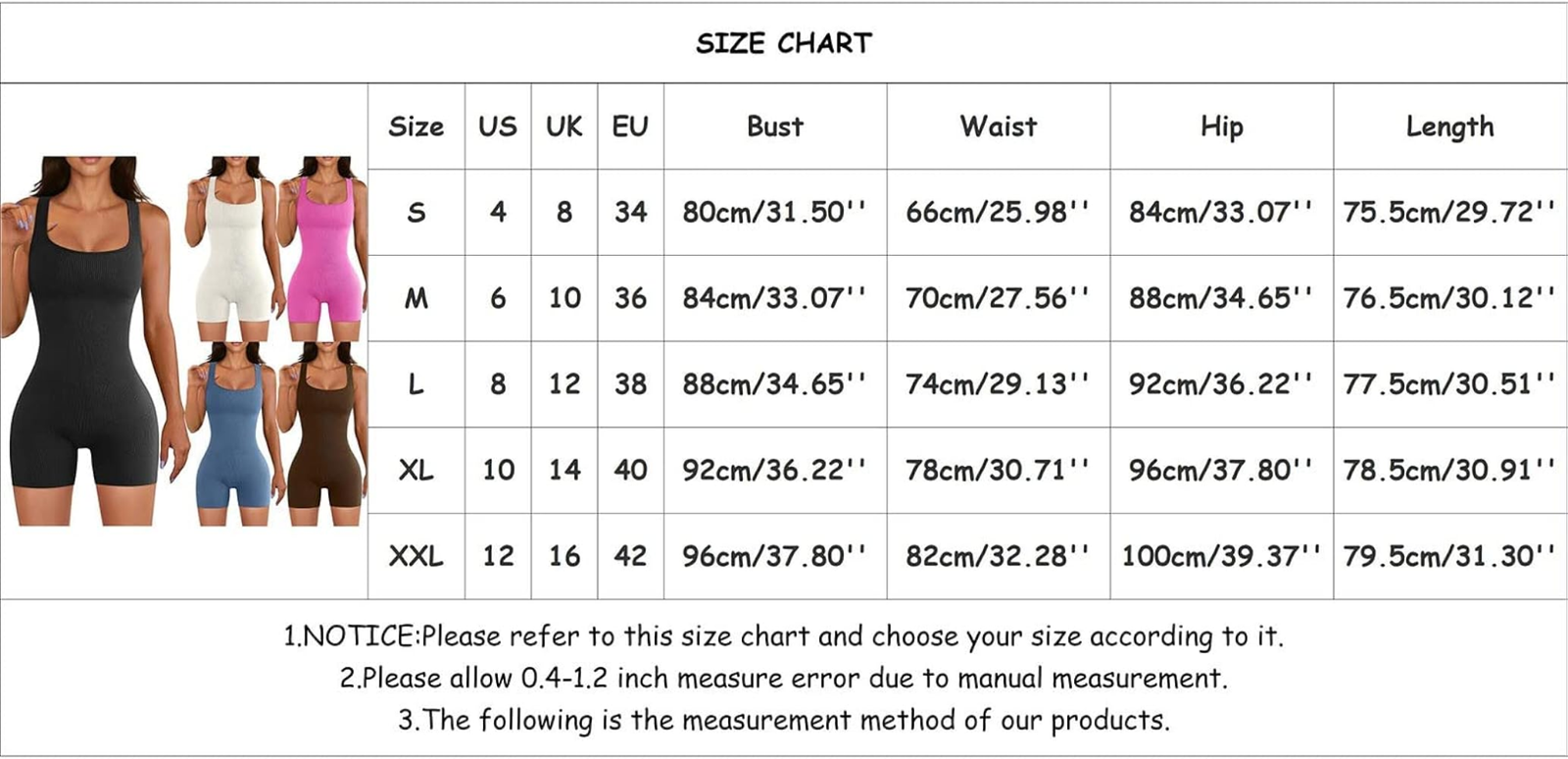

One of the biggest challenges with full body bras is getting the sizing right. Unlike a simple bra, a full body bra needs to fit a woman's torso, bust, and hips all at once. This means precise pattern grading. It means understanding how different body types vary across markets. For example, a full body bra for the European market might need different proportions compared to one for the Asian market. We work to develop size charts that are truly inclusive. We do not just scale up or down. We adjust measurements in key areas to ensure a perfect fit for a wide range of women. We also perform thorough fit testing. This involves trying samples on different body shapes. We check for common fit issues like rolling fabric or uncomfortable pressure points. This ensures the final product provides optimal comfort and support for diverse customers. This meticulous approach is vital for businesses selling to broad markets.

Material Selection and Fabric Performance

What materials make a full body bra comfortable and effective? We pick the best.

Material selection and fabric performance are crucial for full body bras, as they demand textiles that offer a delicate balance of stretch, compression, breathability, and durability, ensuring comfort, shaping effectiveness, and long-lasting wear without compromising on skin-friendliness.

The materials used in a full body bra are essential. They do a big job. They need to provide support. They need to offer shaping. They need to be comfortable for many hours. This means we must choose fabrics that have a very specific set of properties. For example, a good full body bra will often use a blend of nylon and spandex. This gives it the right amount of stretch and compression. But it also needs to be breathable. Otherwise, it will feel hot and uncomfortable. We carefully select materials that can hold their shape well after many washes. They also need to be soft against the skin, free from irritants. We look for fabrics that can wick away moisture. Our expertise in sourcing and using advanced fabrics helps us create full body bras that meet these demands. This ensures comfort and durability, making them a reliable choice for our partners.

Manufacturer Compliance and Certification

Are we a reliable and ethical partner? Our compliance shows our commitment.

Manufacturer compliance and certification are non-negotiable for B2B sourcing, as they prove adherence to ethical labor practices, environmental standards, and product safety regulations, providing buyers with assurance of legal, responsible production and mitigating supply chain risks effectively.

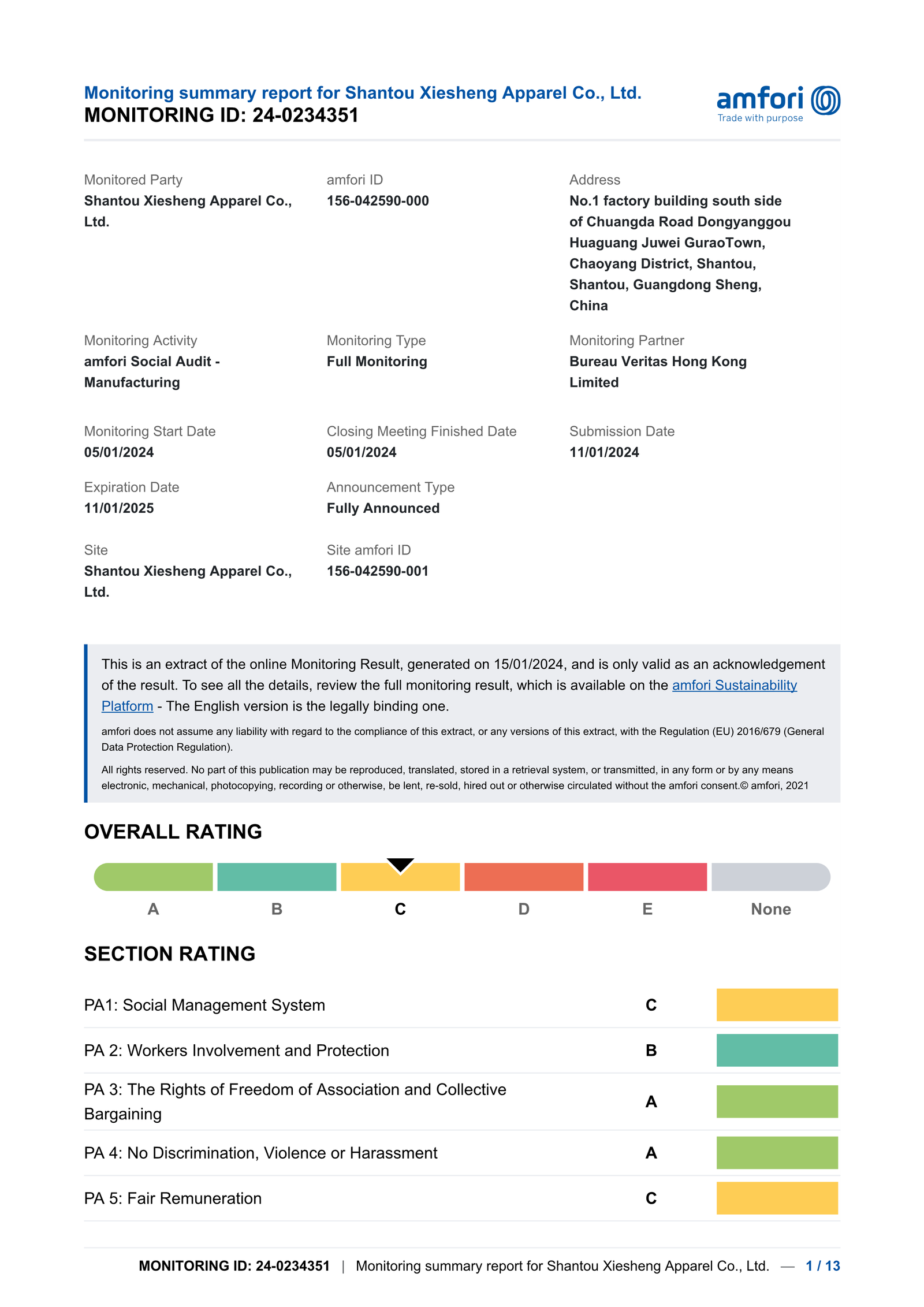

For any B2B buyer, trusting their manufacturer is key. This is especially true for complex items like full body bras. Manufacturer compliance and certification are very important here. It shows that we, as a factory, follow industry standards. For example, we hold BSCI and ISO qualification certificates. BSCI ensures that we follow ethical labor practices. It means our workers are treated fairly. ISO shows our commitment to quality management systems. These certifications are not just pieces of paper. They prove our dedication to responsible and high-quality production. They give our partners confidence. They know they are working with a supplier that meets international standards. This reduces risks for our partners. It ensures their supply chain is not only efficient but also ethical and transparent.

Efficient Communication and Order Management

How do we keep your full body bra orders on track? Through clear and fast talking.

Efficient communication and order management are vital for B2B full body bra sourcing, involving clear, timely exchanges between buyer and manufacturer, precise tracking of order statuses, and proactive problem-solving to ensure smooth execution, on-time delivery, and overall client satisfaction.

When you are ordering a complex product like a full body bra, clear communication is everything. Delays or misunderstandings can have big impacts.We are equipped with a variety of convenient communication tools, including WhatsApp, Gmail and WeChat, to ensure timely and smooth communication with you. In our past cooperation with customers, with these tools, we have achieved efficient communication and received positive feedback. We focus on efficient communication and good order management. This means we have dedicated teams who work closely with our partners. They provide updates on production progress. They answer questions quickly. They handle any issues that come up. For example, if there is a question about a specific trim or a delivery date, we respond fast. Our team of over 300 workers gives us the ability to handle large orders. But good management ensures each order gets the attention it needs. This efficient process ensures that our partners always know the status of their orders. It helps us deliver on time and to specification, building strong working relationships.

Quality Control and Sample Testing

How do we guarantee every full body bra is perfect? With strict checks and tests.

Quality control and sample testing are essential, involving rigorous inspections at every production stage—from material intake to final garment—and mandatory sample testing to verify fit, comfort, durability, and compliance with all specifications, ensuring consistent excellence in every full body bra.

For full body bras, quality control is more critical than ever. There are simply more moving parts. More seams. More fabric. More potential points of failure if not done right. Our professional QC team, makes sure that every single piece meets our high standards. They do not just check the final product. They check materials at the start. They check stitching during production. They perform fit tests on samples. This involves checking how the full body bra looks and feels on a model. They look for any areas where the fabric might bunch or where pressure points occur. This multi-stage process helps us catch and fix problems early. For example, our capacity includes thousands of units per month for shapewear, which often crosses into full body bra territory. This means our QC team is very experienced with these complex garments. This commitment to thorough quality control and sample testing ensures that every full body bra we ship is perfect.

Conclusion

Overcoming full body bra sourcing challenges means accurate sizing, careful material choice, certified production, clear communication, and strict quality control with sample testing for B2B success.