How Can B2B Businesses Excel in the Full Cup Bra Segment?

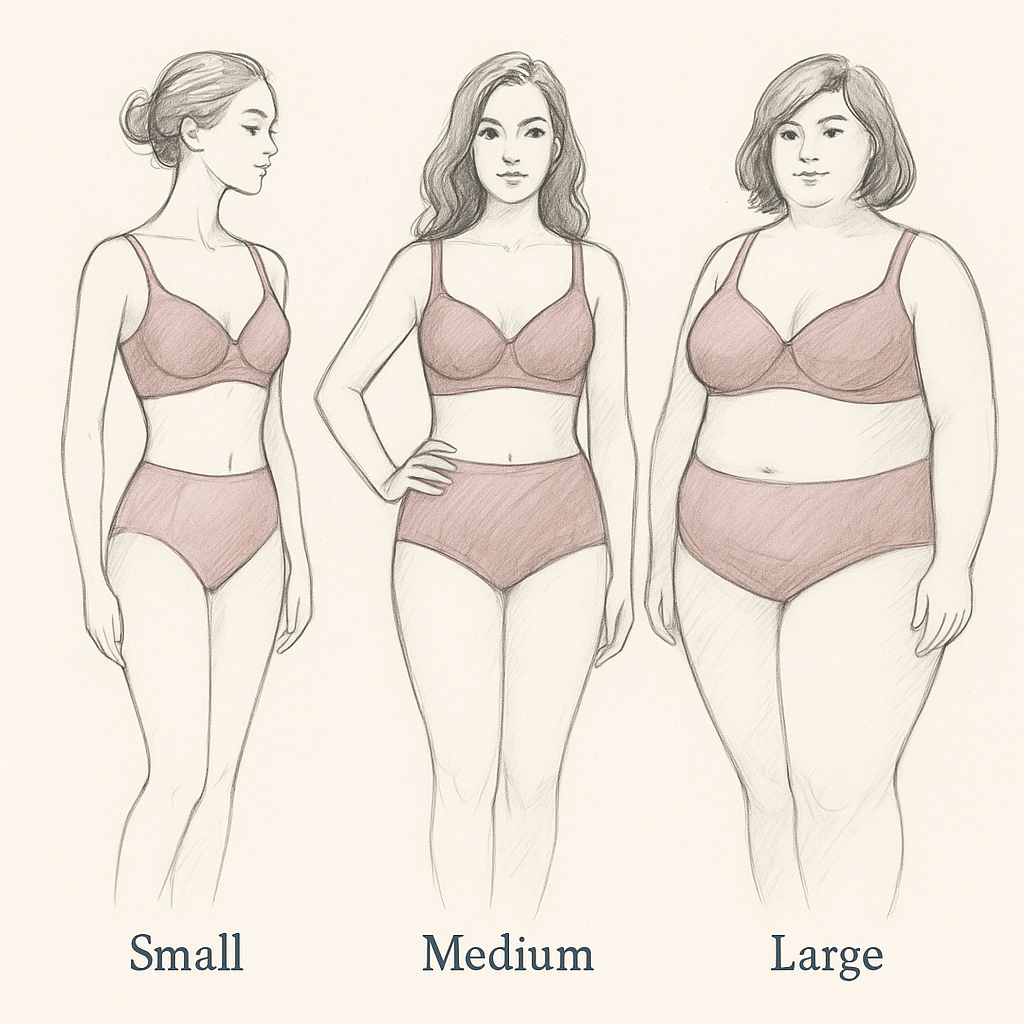

Are your full cup bra sales flat? This growing market demands more than just bigger sizes; it demands comfort, style, and a perfect fit that outdated designs simply cannot provide.

Excel by prioritizing value over price. Focus on modern designs that blend comfort and support, ensure true size inclusivity, collaborate with expert suppliers, and adopt sustainable practices to meet consumer demands.

I remember a conversation with a buyer who saw the full cup market as a necessary but low-profit part of her business. Her existing products were basic, uncomfortable, and had high return rates. She believed these customers were only looking for a low price. I explained that she was looking at it all wrong. This customer is one of the most loyal you can find, but she's also the most underserved. We helped her develop a new line focused on superior engineering—using wider, cushioned straps and 3-part cups for better support. It wasn't the cheapest bra to produce, but it quickly became her most profitable and top-rated line. She learned that in this segment, value and performance will win over a low price every single time.

Why Are Full Cup Bras Gaining So Much Popularity?

Do you think the full cup market is just a small niche? This misconception means you're ignoring a massive, loyal customer base actively searching for brands that finally understand their needs.

Full cup bras are gaining popularity due to the body positivity movement and a growing demand for size-inclusive lingerie. Consumers are rejecting ill-fitting options and actively seeking brands that offer genuine comfort and stylish designs.

The shift in the market isn't just a trend; it's a fundamental change in how women see themselves and what they expect from brands. For decades, the full cup customer was an afterthought. The industry offered them unattractive, purely functional bras while focusing all design innovation on smaller sizes. The rise of body positivity and size inclusivity has empowered this consumer. She is now demanding products that not only fit perfectly but also make her feel beautiful and confident. This group is incredibly vocal online and loyal to brands that listen. For a B2B business, this is a golden opportunity. Capturing this customer means securing a long-term, profitable relationship. They are tired of being ignored and are willing to invest in quality products that finally meet their needs for both function and fashion.

| Old Mindset | New Reality |

|---|---|

| Full cup is a small, niche market. | It is a large, underserved, and rapidly growing segment. |

| Customers only care about price. | Customers prioritize fit, comfort, and quality, and are willing to pay for it. |

| Functional, basic designs are enough. | Customers demand stylish, modern, and fashionable options. |

| Returns are high because of fit issues. | Returns are high because of poor design and engineering. |

What Design Priorities Separate a Great Full Cup Bra from an Average One?

Are your full cup bras just larger versions of your standard bras? This common mistake results in poor fit, customer complaints, and high return rates from a very discerning audience.

Great design prioritizes wider straps to distribute weight, a supportive underband that doesn't roll, deeper cups with side support panels to prevent spillage, and a higher center gore for stability.

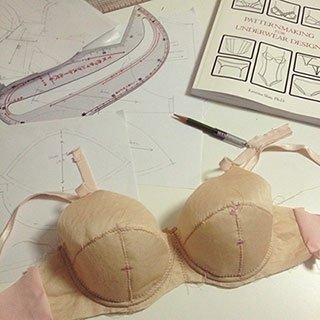

A full cup bra is an piece of engineering. You cannot simply take a pattern for a 34B and scale it up to a 40G; the physics are completely different. The weight and forces involved require specific construction techniques that a generalist manufacturer often doesn't understand.

The Engineering of Support

A great full cup bra has several key features. First, wider, cushioned straps are essential to distribute the weight of the bust across the shoulders, preventing painful digging. Second, the underband provides about 80% of the support, so it must be made from a firm, wide elastic that won't stretch out or roll up. Third, the cups themselves need structure. Instead of a simple molded cup, a 3-part or 4-part seamed cup provides superior lift and shaping. We often include a side support panel, an extra piece of fabric on the outer side of the cup that pushes breast tissue forward, creating a narrower silhouette and preventing side spillage. These are not optional details; they are the core components that make the bra work.

How Does Efficient Sourcing and Supplier Collaboration Work for Full Cup Bras?

Frustrated with suppliers who don't get the complexity of full cup bras? Working with an inexperienced factory leads to costly delays, failed fit tests, and a product that disappoints everyone.

Efficient sourcing requires partnering with a specialist manufacturer with proven experience in plus-size engineering. Collaboration involves trusting their technical ability to properly grade patterns across a wide size range and source the right components.

Finding the right manufacturing partner is the most critical decision you will make in this segment. Many factories will say they can make full cup bras, but very few understand the technical skill involved. The most important skill is pattern grading. The way a pattern must change from a 40G to a 42G is completely different from how it changes from a 34B to a 36B. It requires an experienced pattern maker who specializes in plus-size garments. Another key area is component sourcing. A full cup bra needs stronger underwires, more durable hook-and-eye closures, and wider, more powerful elastics. An expert supplier has an established supply chain for these specific, high-performance materials. Your role as the B2B brand is to provide a clear vision and feedback from your customers. Our role as the manufacturer is to provide the technical execution. This collaborative loop is essential for creating a perfect product.

Why Do Sustainability and Ethics Matter in the Full Cup Market?

Do you think the full cup customer only cares about fit? This assumption ignores that modern consumers, regardless of size, demand ethical production and sustainable materials from the brands they support.

Sustainability and ethics matter because the full cup consumer is often a highly conscious and loyal buyer. Offering products with certifications like OEKO-TEX® and BSCI builds deep trust.

The full cup customer is often a very informed shopper. She has spent years researching brands to find something that works, and she cares about more than just the product itself. She wants to support brands that align with her values. This is why sustainability and ethical manufacturing are not just marketing tools; they are essential for building brand loyalty. When we produce bras using recycled nylon or soft, eco-friendly TENCEL™ Modal, we are meeting a clear consumer demand. More importantly, we provide the proof. Certifications are your guarantee. OEKO-TEX® Standard 100 assures your customer the product is free from harmful chemicals. A social compliance audit like BSCI assures them the garment was made by workers who are treated fairly and work in a safe environment. These certifications are critical for risk management and building a brand that customers can truly trust.

How Can Technology and Data Help You Make Smarter B2B Decisions?

Are you just guessing which full cup sizes to stock? This gamble leads to costly overstock in unpopular sizes and frustrating stockouts in your best-sellers, directly hurting your revenue.

Technology helps by analyzing sales data to predict which sizes and styles are most in-demand. Partnering with a manufacturer who offers low MOQs allows you to test new styles based on this data.

Guesswork is the enemy of profitability, especially in a segment with such a wide range of sizes. This is where data becomes your most powerful tool. By analyzing your own sales data, you can stop ordering a standard size curve and instead focus your inventory investment on the sizes that your specific customers are actually buying. This instantly reduces overstock and prevents lost sales from stockouts. Technology enables a more agile approach. Instead of placing one or two huge orders per year, you can work with a flexible manufacturer like us. Our lower MOQs (500-300 pieces per color) allow you to place smaller, more frequent orders. This means you can test a new color or style based on emerging data without taking a huge financial risk. This data-driven, agile approach transforms your business from being reactive to being predictive, which is the key to winning in a competitive market.

Conclusion

Excelling in the full cup segment means shifting from chasing low costs to creating real value through expert design, ethical sourcing, and a strong, collaborative partnership with your manufacturer.